Macfarlane Packaging Online Shop

X

- Boxes

- Bags

- Postal

-

Protective

- View all Protective

- Bubble Wrap Rolls

-

Bubble Wrap Bags

- View all Bubble Wrap Bags

-

Bubble Wrap Bags

- Bubble Mask

- Bubble Guard

-

Airsac

- View all Airsac

-

Airsac

-

Air Cushioning & Voidfill

- View all Air Cushioning & Voidfill

-

Air Cushioning & Voidfill

- Korrvu

- Foam Rolls

- Instapak

- Geami WrapPak

-

Paper Cushioning & Voidfill

- View all Paper Cushioning & Voidfill

-

Paper Cushioning & Voidfill

- Loosefill & Dispensers

- Mesh Sleeving

- Edge & Corner Protection

- Woodwool & Vermiculite

- Paper

- Tapes

-

Polythene

- View all Polythene

-

Layflat Polythene Tubing

- View all Layflat Polythene Tubing

-

Layflat Polythene Tubing

-

Sealers & Dispensers

- View all Sealers & Dispensers

-

Sealers & Dispensers

- Pallet Top Sheets

- Centrefold Polythene Sheets

- Shrink Wrap

- Stretch

-

Strapping

- View all Strapping

- Hand Applied Strapping

-

Machine Applied Strapping

- View all Machine Applied Strapping

-

Machine Applied Strapping

- Packing Room & Warehouse

- Boxes

- Bags

- Postal

-

Protective

- View all Protective

- Bubble Wrap Rolls

-

Bubble Wrap Bags

- View all Bubble Wrap Bags

-

Bubble Wrap Bags

- Bubble Mask

- Bubble Guard

-

Airsac

- View all Airsac

-

Airsac

-

Air Cushioning & Voidfill

- View all Air Cushioning & Voidfill

-

Air Cushioning & Voidfill

- Korrvu

- Foam Rolls

- Instapak

- Geami WrapPak

-

Paper Cushioning & Voidfill

- View all Paper Cushioning & Voidfill

-

Paper Cushioning & Voidfill

- Loosefill & Dispensers

- Mesh Sleeving

- Edge & Corner Protection

- Woodwool & Vermiculite

- Paper

- Tapes

-

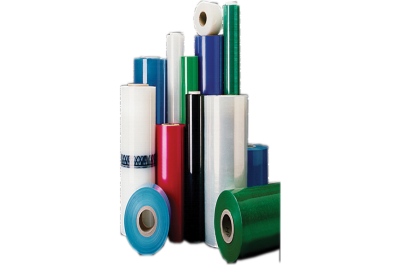

Polythene

- View all Polythene

-

Layflat Polythene Tubing

- View all Layflat Polythene Tubing

-

Layflat Polythene Tubing

-

Sealers & Dispensers

- View all Sealers & Dispensers

-

Sealers & Dispensers

- Pallet Top Sheets

- Centrefold Polythene Sheets

- Shrink Wrap

- Stretch

-

Strapping

- View all Strapping

- Hand Applied Strapping

-

Machine Applied Strapping

- View all Machine Applied Strapping

-

Machine Applied Strapping

- Packing Room & Warehouse

When selecting stretch films consider the following:

Performance - select a stretch film that provides the right yield strength and performance for the loads being wrapped is crucial.

The yield strength denotes the amount of stress a stretch film can withstand without permanently having plastic deformation.

Prior to reaching the yield point, a stretch film will elastically deform but return to it’s original shape once the stress is removed.

Products - consider the products being wrapped. Also look at the weight load (typically per pallet), the load profile as described below, and the transit process the load will experience.

Time, use and cost use - hand wrapping is best suited for smaller or sporadic stretch film wrapping requirements.

Introducing machine wrapping may ultimately save time, resources and packaging materials

Overlapping - This is a technique for covering the top of your pallet using polythene top sheets.

This protects your products and provides a downward force on the pallet load.

When overlapping hand applied films, it is recommended users allow up to a 50% overlap.

If using machine applied films, users should allow a 50 mm overlap, regardless of the film width.

Banding - This refers to applying multiple wraps of stretch film to a particular area of a pallet to reinforce the load or band multiple units together.

Neckdown - This happens when a film loses its dispensing roll width and narrows down while being stretched.

Neckdown reduces the coverage each wrap provides thereby making it likely that more wrap rotations and more film will be needed to wrap a load or pallet.